Floor Operated Coil Car

Product Details:

- Control System Pendant Control / Remote Control

- Wheel Type Solid Rubber Wheels

- Features High Load Endurance, Safety Lock Mechanism

- Rack Capacity Up to 5 Tons

- Motor Type Heavy Duty Induction Motor

- Equipment Type Floor Operated Coil Car

- Lifting Speed 5-10 m/min

- Click to view more

Floor Operated Coil Car Price And Quantity

- 1 Unit

- 1500000 INR

Floor Operated Coil Car Product Specifications

- 360 Degree Manual Rotation

- Electric

- 3 kW

- Integrated Steel Handle

- New

- 5-10 m/min

- Heavy Duty, Robust Construction

- 600 mm

- Smooth Operation, Anti-Corrosive Finish

- 5000 kg

- 5 Ton

- Floor Operated Coil Car

- 415 V AC

- Pendant Control / Remote Control

- Solid Rubber Wheels

- Up to 5 Tons

- Heavy Duty Induction Motor

- High Load Endurance, Safety Lock Mechanism

Floor Operated Coil Car Trade Information

- 100 Unit Per Month

- 2-3 Months

Product Description

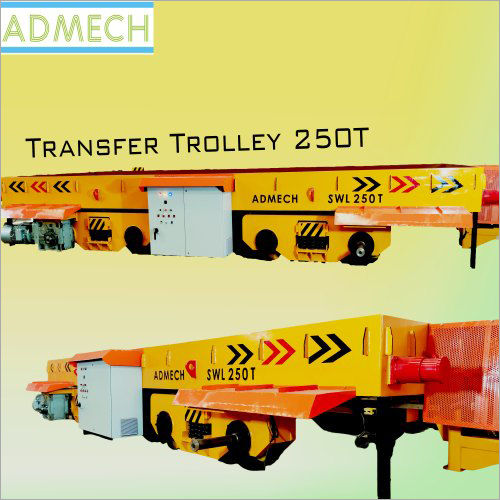

Floor Operated Coil Car

Floor Operated Coil Car is a heavy materials handling unit which is mainly used for the transportation of large steel rolls to different machining areas within the industrial and manufacturing plants. It is driven with the help of high performance electrical motors to give power to the wheels. The structural frame is fabricated by using rigid engineering materials which makes it capable to withstand heavy loads and impact forces. It is also provided with a programmable logical control unit to control this machine.

Product Details :

|

Capacity |

As per customer requirement |

We manufacture and offer well-engineered Floor Operated Coil Car. There are various specifications and capacities available. The system is designed for low maintenance and high performance.

Technical Specifications

|

Surface Finish |

Color Coated |

|

Capacity |

Approx 10 Ton |

|

Color |

Yellow |

|

Brand |

Admech |

|

Material |

Mild Steel |

|

Usage/Application |

Industrial |

Robust Construction for Demanding Environments

Built from mild and alloy steel, the Floor Operated Coil Car brings outstanding durability to industrial coil management. Its heavy-duty structure and anti-corrosive finishes withstand wear over long-term operations in steel plants and warehouses. The reinforced platform and solid rubber wheels further extend its operational life, making it ideal for rigorous, continuous usage.

Advanced Hydraulic Drive for Smooth Coil Handling

The hydraulic drive system delivers precise movement and stable lifting, supporting up to 5 tons per load. Integrated with heavy-duty induction motors and an anti-slip curved platform, the coil car offers both efficiency and safety. Operators can use either pendant or remote controls for seamless maneuvering, contributing to increased productivity and reduced handling risks.

Comprehensive Safety & Control Features

Safety is paramount with emergency stop, overload protection, and an innovative safety lock mechanism. The 360-degree manual rotation and ergonomic steel handle enhance operator control, while the anti-slip surface on the load support platform prevents accidental slips. Combined with reliable motor power and low power consumption, the coil car meets demanding safety and efficiency standards.

FAQs of Floor Operated Coil Car:

Q: How does the Floor Operated Coil Car ensure safe coil handling in industrial environments?

A: The coil car is equipped with a hydraulic-powered lifting system, an anti-slip curved platform, emergency stop functionality, overload protection, and a safety lock mechanism. These features collectively minimize risks and provide secure, controlled movement of heavy coils during operation.Q: What types of coils and load capacities can this equipment handle?

A: It is designed for handling steel coils in plants, warehouses, and manufacturing units, supporting up to 5 tons per load. The rack capacity is also up to 5 tons, making it ideal for heavy-duty, high-volume operations.Q: When should the Floor Operated Coil Car be used for coil transport?

A: This equipment should be used whenever heavy coils need to be transported, lifted, or positioned within indoor or covered outdoor environments such as steel plants or manufacturing facilities. Its design supports regular operational cycles for both short and extended shifts.Q: Where can the Floor Operated Coil Car operate efficiently?

A: It is suitable for indoor and covered outdoor spaces where coil handling is required. Typical settings include steel processing plants, manufacturing units, and large warehouses.Q: What is the process for operating and controlling the coil car?

A: Operation is managed via an integrated pendant control or optional remote control, allowing for precise lift and movement. The manual handle and 360-degree rotation capabilities assist with positioning, while solid rubber wheels ensure smooth transit on various surfaces.Q: What benefits does the powder coated or painted finish provide?

A: The powder coated or painted finish offers excellent resistance to corrosion and wear, maintaining the coil cars structural integrity and appearance over prolonged industrial usage.Q: How does the drive mechanism contribute to the coil cars performance?

A: The hydraulic-powered drive mechanism, supported by a heavy-duty induction motor, provides consistent lifting speed (510 m/min) and smooth operation, optimizing productivity and ensuring stable handling of heavy loads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free